For concrete paver joints up to 1" in traditional applications

setting time 1hr

sets above 32°F (0°C)

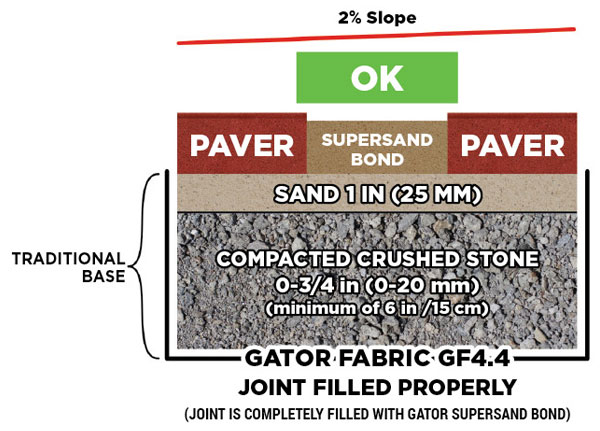

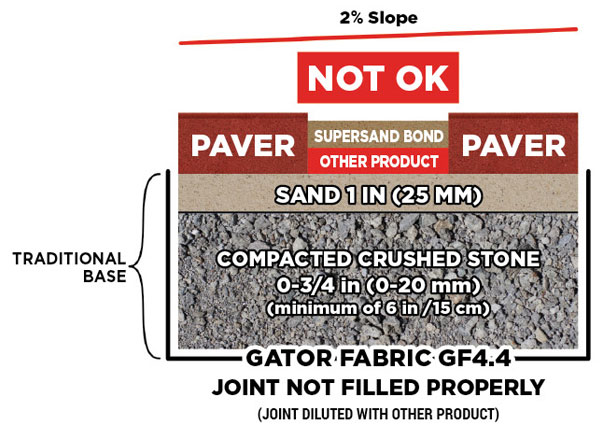

SUPERSAND BOND is a unique mixture of polymer binders and calibrated sand available in Beige and Slate Grey. The installation of SUPERSAND BOND is almost identical to using regular paver joint sand except for the application of water. Once SUPERSAND BOND polymeric sand sets, it becomes very firm and locks between the paver joints while still retaining flexibility and providing a long lasting, durable jointing material. SUPERSAND BOND is recommended for a variety of uses including pool decks, patios, footpaths, driveways, parking spaces, pavements etc.

Maintenance of paved surface

When maintaining the paver surface, apply Gator Shampoo to clean the entire paved surface including the paver joints. Wash, rinse and remove any residue by using a hose and a watering gun set to shower with the normal maximum water pressure from any residential or commercial building (typically 80 psi/550 kPa).

Moss

SUPERSAND BOND will not cause nor prevent moss, mold or mildew. Moss, mold and mildew are caused by certain on site conditions including excess moisture, shade, absence of ventilation, inadequate cleaning or maintenance, presence of soil or other organic debris left on the product.

Clay Pavers

If used on clay pavers make sure they are 100% dry. Clay pavers tend to hold moisture, which can prematurely activate the SUPERSAND BOND while the sand is being spread over the paver surface, leaving a residue (always apply on a test area before using the SUPERSAND BOND on clay pavers).

| Per 50 lb (22.7 kg) bag (Paver 2-3/8” (6 cm) in height) | NARROW JOINTS 1/8” to 3/8” (3-9 mm) | WIDE JOINTS 3/4” to 1” (19-25 mm) |

|---|---|---|

| Beige, Slate Grey | 65-85 sq. ft. (6-7.9 sq.m.) | 22-42 sq. ft. (2-3.88 sq. m.) |

| Product | Size | Units per Pallet |

|---|---|---|

| SUPERSAND BOND – Beige | 50 lb (22.7 kg) | 56 USA / 70 CAN |

| SUPERSAND BOND – Slate Grey | 50 lb (22.7 kg) | 56 USA / 70 CAN |

Maximum joint width: 1″ (2.5 cm)

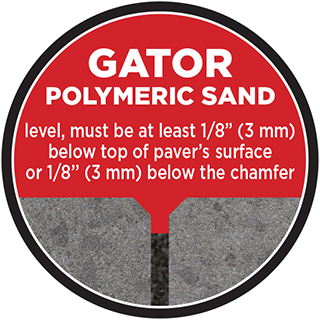

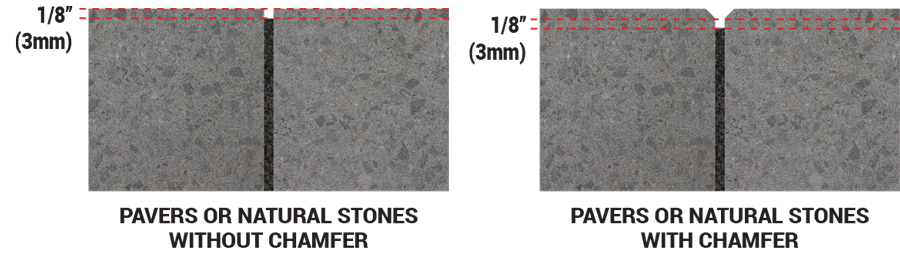

POLYMERIC SAND REQUIREMENTS

Minimum joint width: 1/8″ (3 mm)

Maximum joint width: 1″ (2.5 cm)

Minimum joint depth: 1 1/2″ (38 mm)

Sand or ASTM No. 9 Stone can be used under pavers

NEVER USE SUPERSAND BOND WHEN PAVERS ARE INSTALLED ON A CONCRETE SLAB. INSTEAD, USE ALLIANCE GATOR MAXX SAND (Offered only in USA).

The water used in steps 7 to 9 will activate a bonding action as well as condensing SUPERSAND BOND in the joints. It is important to water the SUPERSAND BOND a total of 3 times, as per steps 7, 8 and 9. Too little water will not properly activate the SUPERSAND BOND and will reduce the final performance. If steps 7 to 10 are not done properly, a white haze may appear on paver surface after installation. This is due to excess SUPERSAND BOND residue left on paver surfaces. This haze will dissipate over time, or it could be removed by using Gator Clean Efflorescence Cleaner.

THE PARTIES AGREE THAT REFUND OF THE PURCHASE PRICE AS STATED IS THE ONLY OBLIGATION OF THE MANUFACTURER. IN ALL EVENTS, THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY OTHER DAMAGES OR COSTS WHATSOEVER, (INCLUDING REMOVAL OR REINSTALLATION OF SAND OR PAVERS) DIRECT OR CONSEQUENTIAL. TO THE EXTENT PERMITTED BY LAW, THE MANUFACTURER EXCLUDES ANY IMPLIED WARRANTY OF QUALITY, MERCHANTABILITY OR FITNESS FOR PURPOSE. ALLIANCE DESIGNER PRODUCTS INC. excludes any responsibility whatsoever for the presence of moss, mold, mildew, or similar factors that may occur on the product after its installation. The presence of moss, mold or mildew is caused by the particular on-site conditions, including excess moisture, shade, absence of ventilation, inadequate cleaning or maintenance, presence of soil or other organic debris left on the product after installation. ALLIANCE DESIGNER PRODUCTS INC. excludes any responsibility for use of SUPERSAND BOND for any installation not installed to manufacturer’s specifications and ICPI Tech Spec #2.

We use cookies to help improve your experience. By continuing to use this website, you agree to our Privacy Policy.