Gator Stone Bond

Pathway stabilizer

Easy 1 coat application

Residential & Commercial use

GATOR STONE BOND is sold ONLY in the following states: California, Nevada, Texas, Arizona

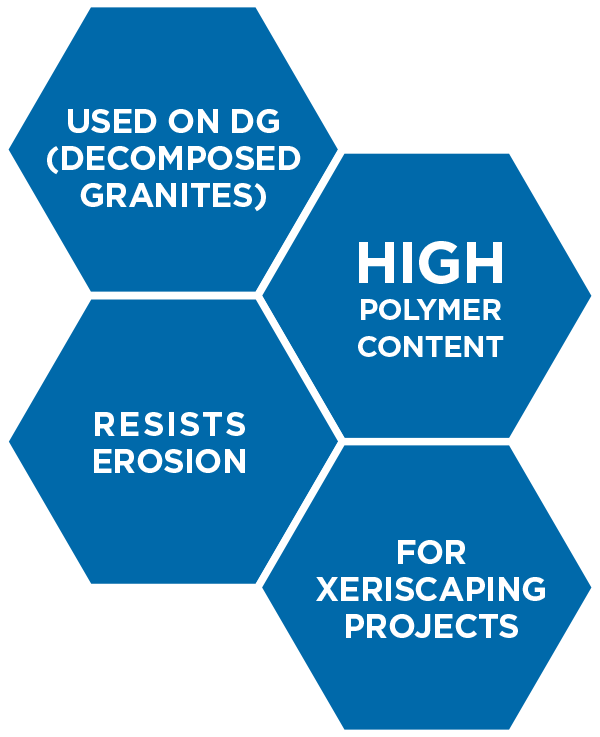

GATOR STONE BOND is a unique blend of acrylic polymers designed to bind together a wide variety of small aggregates commonly referred to as DG (decomposed granite): pathway mixes, crusher runs, concrete sand, etc.

- Pedestrian applications

- Pathways

- Alleys

- Patios

- Ready to use right out of the container

- Easy-to-apply one-coat application

- Reduces dust, gravel migration and erosion

- Allows the use of Patio/Pathway year round

- No special tools or skills required to build

- Build using local aggregates (stone mixes such as: 3/8 minus, 1/4 minus or 3/16 minus)

- Creates a strong bond on a wide variety of aggregates

- Resists surface erosion from both rainwater and foot traffic

- Will not harm plants or aquatic life

- EPA-compliant

| Gator Stone Bond | Residential | Commercial |

|---|---|---|

| 1 U.S. gal. (3.78 L) | 15 sq. ft. (1.4 sq. m.) | 10 sq. ft. (0.9 sq. m.) |

For pedestrian applications

| Product | Retail Size | Per Box | Per Pallet |

|---|---|---|---|

| GATOR STONE BOND | 1 U.S. gal. (3.78 L) | 4 | 24 boxes |

| GATOR STONE BOND | 5 U.S. gal. (19 L) | 48 pails |

INSTALLATION INSTRUCTIONS

PLEASE NOTE

- GATOR STONE BOND are not sealers, we do not recommend using it as such.

- Where the vibratory plate will not reach use a hand tamper or a block of wood and a hammer, compact corners and other hard to reach areas.

- All crushed stone aggregates are not created equal, when in doubt, do a test area.

- GATOR STONE BOND does work on sands, but sands are not considered as strong “structurally speaking” as a crushed stone mix with larger size stones like a 3/8 minus.

- GATOR STONE BOND may slightly darken the crushed stone mix.

- GATOR STONE BOND is not concrete, expect that some surface aggregates will become loose over time.

- In some instances a crack may appear, if the foundation is not well prepared.

- Slope the surface so water will run off.

- Form or taper the edges (if you choose to form, leave them in place when done).

- Allow 24 to 48 hours at a temperature above 60°F (16°C) for surface to cure.

- Do not apply GATOR STONE BOND if rain is expected within 48 hours.

- Please store GATOR STONE BOND container at above 32°F (0°C).

- GATOR STONE BOND is sold ONLY in the following states: California, Nevada, Texas, Arizona

AGGREGATE SELECTION AND BASE PREPARATION

A • AGGREGATE SELECTION FOR FINAL SURFACE

Select an aggregate that contains a variety of sizes. For instance, crushed stone mixes such as 3/8 minus, 1/4 minus or 3/16 minus work well with GATOR STONE BOND, whereas single size aggregates like 3/8 rock or pea gravel are not suitable. Screenings with extremely high fine content are not suitable either. To ensure compatibility of selected aggregate with GATOR STONE BOND, prepare a test area.

B • STRUCTURAL STONE BASE PREPARATION

Before starting the actual project, factors such as climate, native soil type and amount of use, should be taken into consideration. As a rule of thumb, “The better the base preparation, the better the results.”

Option 1 – For optimum performance, install 4 to 6 in of 3/4 minus crushed stone, then compact using a vibratory plate compactor.

Option 2 – Install 2 to 4 in of 3/4 minus or 3/8 minus, 1/4 minus or 3/16 minus crushed stone, then compact using a vibratory plate compactor. In restricted areas where a compactor will not fit, use a hand tamper.

APPLICATION STEPS

(For a new surface)

STEP 1 • SURFACE AGGREGATE:

- Always refer to the latest GATOR STONE BOND Technical Data Sheet (TDS) at AllianceGator.com before installing GATOR STONE BOND.

- Spread a maximum of 1 in (2.5 cm) surface aggregate over the compacted structural stone base. Rake or screed to the desired level, a minimum slope of 2 degrees to allow water runoff. Do not compact until after GATOR STONE BOND has been applied.

STEP 2

Using a watering can or pump sprayer, apply the GATOR STONE BOND to the surface at the rate of 15 sq. ft. (1.4 sq. m.) per gallon (3.78 L) for residential pedestrian use, or 10 sq. ft. (0.9 sq. m.) per gallon (3.78 L) for commercial pedestrian use. Allow GATOR STONE BOND to fully penetrate through the material.

APPLICATION STEPS

(For rebuilding an existing surface)

STEP 1

STEP 2

Apply GATOR STONE BOND at the rate of 15 sq. ft. (1.4 sq. m.) per gallon (3.78 L); allow liquid to penetrate.

STEP 3

APPLICATION STEPS

(For maintaining an existing surface)

STEP 1

Make repairs as needed.

STEP 2

Apply GATOR STONE BOND at the rate of 20 to 45 sq. ft. (1.9 to 4.2 sq. m.) per gallon. Some judgement will be needed, as consideration for absorption and desired results should be taken into account.